Consumer Guide

Lumber is sawn into many different specifications or grades. So knowing the right grade to buy is very important to customers. It’s also important that the grading system be uniform and consistent.

In our region the Maritime Lumber Bureau, founded in 1938, is the agency which ensures the integrity and uniformity of lumber grading standards. The Bureau’s authority extends through the whole of North America, but exists primarily in the Maritimes and Eastern U.S.A.

Purchasing a higher grade than required may waste money. Purchasing a lower grade can result in an inferior job, or even worse. For example, using sub-grade lumber for roof trusses or walls could mean that these areas may not withstand a heavy snow load. So buying the correct species and the right grade of lumber is very important.

This web site is designed to assist customer’s of the Maritime Lumber Bureau’s nearly 150 member firms and affiliates in selecting the right materials for their particular project. It contains some of the questions most frequently asked by lumber buyers. We hope that you find it useful.

Q.What is a grade stamp?

Answer: The Grade Stamp is stamped on each piece of lumber. The National Building Code of Canada (NBCC) requires the use of grade stamped lumber for all engineered wood structures including houses and small buildings. The Grade Stamp clearly shows the species group and quality standard of that particular piece of lumber.

Buying lumber which is grade stamped assures you of a consistent specified quality. Always look for the stamp bearing the letters M.L.B., short for Maritime Lumber Bureau, signifying you are buying a product produced in our region and manufactured to a specific standard.

Shown below is the M.L.B. Grade Stamp and what some of the most commonly used figures and numbers within that stamp mean.

Q.But what if I’m not sure what I want?

Answer: Then be sure to ask you dealer. Explain what you want to build. Determine exactly what grade you want before you place the order. This can save you both time and money, resulting in a better job and ensuring that you receive exactly what you ordered.

Q. What are the differences in grades?

Answer: Lumber is usually ordered in “No.2 & Better” grade mix. In Canada, identical design values are given for the No.1 or No.2 Grade lumber. The differences between those two grades relate primarily to the appearance of the material. A higher grade, Select Structural, is also sometimes available.

Q.What’s the difference between “dressed” and “rough” lumber?

Answer: Rough lumber has a rough surface texture, usually still showing saw marks which would later be removed by the planer.

“Dressed” or “surfaced” lumber has been put through a planing machine to give smoothness and uniformity of size. Lumber may be purchased which has been dressed by a planing machine on one side (S1S), two sides (S2S), one edge (S1E), two edges (S2E), or a combination of sides and edges (S1S1E, S1S2E, or S4S).

Q.Sometimes the edges of construction lumber are square (and sharper) and sometimes they are rounded. Why is this?

Answer: There is no difference structurally. It’s really a matter of preference.

Q.I’m confused about sizes! I asked for a 2″ x 6″ but it only measured 1 9/16″ x 5 5/8″. Why?

Answer: Probably by custom. Early mills sawed a 2″ x 6″ to those dimensions. All lumber dries and shrinks and today most construction lumber is dressed or planed down to a smoother surface than rough lumber has. So today the industry has established definate dimensions. The nominal size (what we all call it) is a 2″ x 6″. But the actual size of a 2″ x 6″ surfaced or dressed (meaning planed), green(meaning wet or undried) is 1 9/16″ x 5 5/8″.

Moisture Content also affects sizes. At 15% moisture content, a 2″ x 6″ will measure 1 1/2″ x 5 1/2″. At varying moisture contents, the size will differ slightly.

Customers can still buy lumber sawn to full size or any common dimension by special order. This is usually sold as rough or unplaned material.

Q.What’s the difference between dry and green lumber?

Answer: By definition, dry lumber has a moisture content of 19% or less. Construction lumber or boards surfaced at a moisture content of 19% or less may be stamped “S-Dry”. On lumber with over 19% moisture content the stamp will show “S-Grn”.

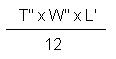

Q.I’m confused about measurements when ordering. What’s the difference between “linear” measure and “board feet”?

Answer: One board foot is the nominal quantity of lumber derived from a piece of rough green lumber 1 inch thick and 1 foot wide by 1 foot long. For example, a 2″ x 4″ x 8′ Stud contains 5.33 Board Feet.

A linear foot is the quantity of lumber derived from the total length of a piece of lumber. For example a 2″ x 4″ x 8′ Stud contains 8 linear feet.

Q.For mouldings, what species should I use for strength? Which species take paint better and what about finger-jointed mouldings?

Answer: Again, it’s wise to tell your supplier how you intend to use the mouldings. Most mouldings aren’t used as a structural member, so strength isn’t too important. However, durability may be important in some areas. If it’s going to be painted then the species shouldn’t matter and finger-jointed material may be preferred as it may be less expensive and may have defects such as knots removed.

Q.I’m building a house and want to be sure I use the right strength and quality of lumber for trusses, joints, rafters, and so on. How do I find out this information?

Answer: A Maritime Lumber Bureau member firm can help you. In any event, information such as span tables, design values, and structural design is fully covered in Canada’s National Building Code. Your local carpenter, architect, or engineer can be very helpful in specifying what you need. In addition, the Canadian Wood Council is an excellent source for wood design data.